Discover what we do

Our Services

We combine advanced digital fabrication with skilled craftsmanship to deliver high-quality stonework for public, commercial and architectural projects. From precision CNC machining to hand-finished engraving and inlay, our services allow us to enhance natural stone with accuracy, durability and attention to detail.

Sandblast

Sandblasting is a controlled process used to clean, texture and engrave stone surfaces. By carefully adjusting pressure and technique, we create consistent finishes for detailed engraved designs, making it ideal for bespoke decorative stone engraving.

CNC

Advanced CNC machining allows us to cut and shape stone from multiple angles in a single setup, delivering complex forms, precise detail and high-quality finishes with maximum efficiency.

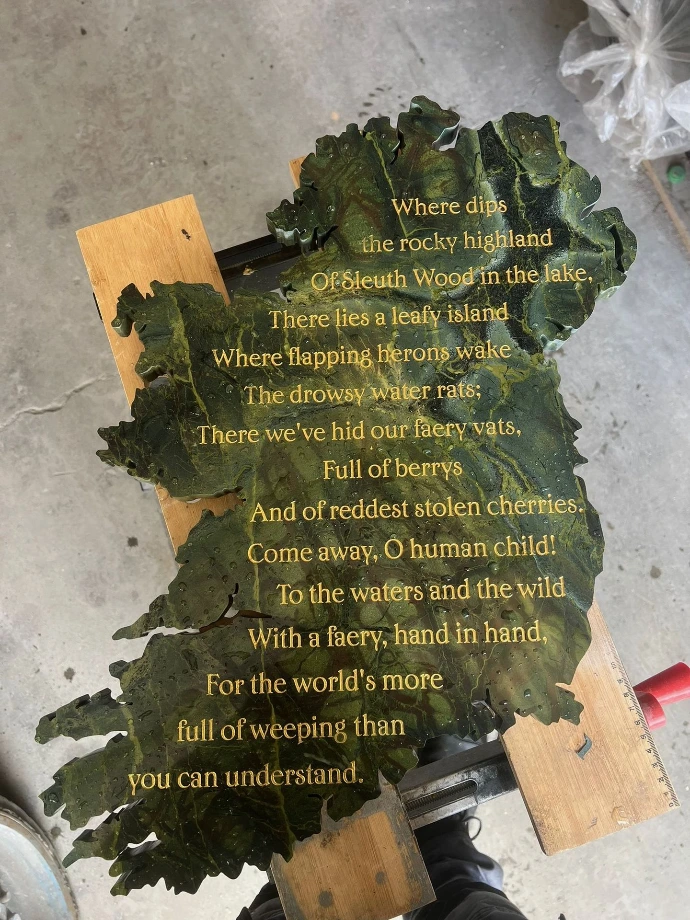

Engraving

Fine detailed engraving can be produced using sandblasting or CNC machining, depending on the required finish and level of detail. Engraved elements can be enhanced with paint, gold leaf, epoxy resin or metal inlays to achieve the desired visual effect and durability.

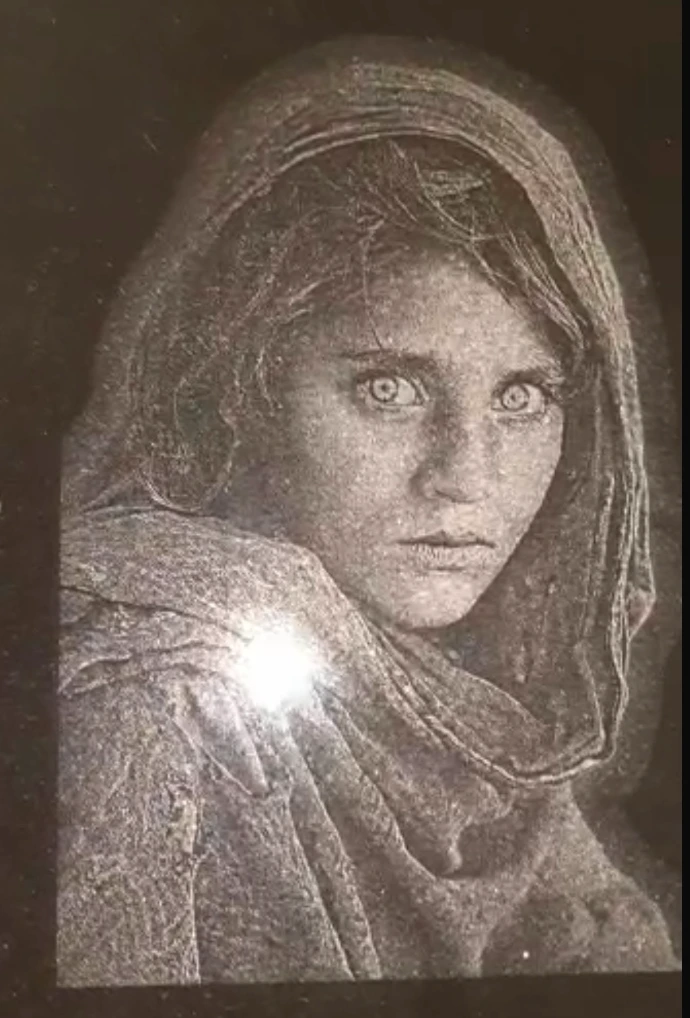

Impact etching

Impact etching is a precision engraving process used to reproduce detailed images and graphics on stone, producing durable, high-contrast results ideal for memorials and commercial projects

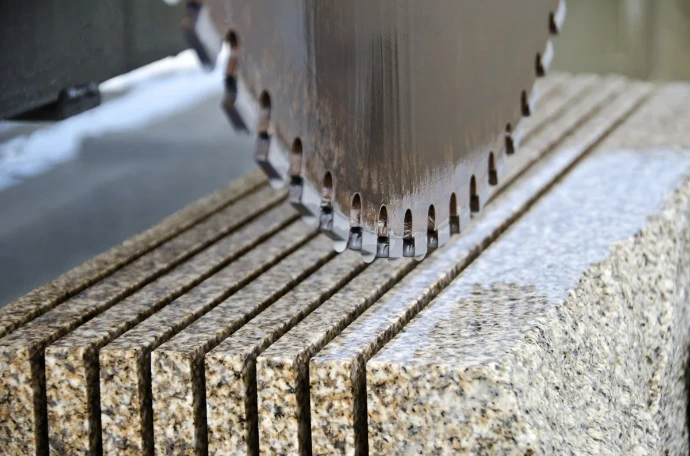

Cutting

Cutting Slabs, blocks and metals including intricate shapes using the latest technologies in diamond tooling, waterjet and laser cutting.

Restoration

Fine detailed engraving can be produced using sandblasting or CNC machining, depending on the required finish and level of detail. Engraved elements can be enhanced with paint, gold leaf, epoxy resin or metal inlays to achieve the desired visual effect and durability.

Materials we work with

Natural Stone

We work with a wide range of natural stones, including granite, limestone, sandstone and marble. Each material offers distinct colour, texture and performance characteristics, making natural stone ideal for engraved features, signage and durable public-realm installations.

Metals

We work with stainless steel, brass and bronze, selected for their strength, durability and visual contrast when combined with stone. These metals are commonly used for inlay, lettering and detailing, adding clarity, longevity and a refined finish to public-realm, architectural and commemorative projects.

Glass, Ceramic & Porcelain tiles

We engrave glass, ceramic and porcelain tiles using controlled sandblasting techniques to create crisp, permanent detail. This process allows for decorative patterns, text and imagery while maintaining the strength and surface integrity of the material, making it suitable for architectural, interior and public-realm applications.

Frequently asked questions

We work with a wide range of materials, including natural stone such as granite, limestone, sandstone and marble, as well as metals including stainless steel, brass and bronze. We also engrave glass, ceramic and porcelain tiles using sandblasting, cnc and hand techniques.

We offer a 30-day return policy for all products. Items must be in their original condition, unused, and include the receipt or proof of purchase. Refunds are processed within 5-7 business days of receiving the returned item.

Discover our featured projects

Some our recently completed works